Off Limits Materials – Now Not So Off Limits!

In the past 15 years major markets have opened up to the small entrepreneur. Major areas of development were off limits to the small guy, but now are in their hands.

The combination of old school techniques matched with new technologies has opened a door that was not possible even 15 years ago.

Simple 3-d Printing technology was only available in $20K machines, not until the major breakthroughs in Filament printing (FDM) and Stereolithography (SLA) printing have complexities in design been even attempted.

I run into this all the time when I introduce new technologies to develop our products. The people that I am dealing with have never seen approaches like we are doing, because they just have not been considered.

In this article we will review the development of a Model-T Go Kart part that is to be made out of cast iron. Cast iron typically is cast using permanent patterns as the starting point. In this article we are shattering the paradigm and are using simple CNC router technology to develop complex molds and parts.

In this article we will review the development of a Model-T Go Kart part that is to be made out of cast iron. Cast iron typically is cast using permanent patterns as the starting point. In this article we are shattering the paradigm and are using simple CNC router technology to develop complex molds and parts.

The Barriers to Entry

The casting industry was developed ages ago to mass produce complex shapes quickly and simply. The simple bronze sword was cast using clay molds. These clay molds being developed from masters (patterns) that expert craftsman of the age whittled into existence.

The basic technology of trying to hold a molten liquid and not have the container disintegrate but impart the precious shapes to the molten material has been the main struggle of metallurgist for millennia.

During the trek of development heat resistant materials, we call them refractory materials have been developed and discovered:

The word refractory comes from Latin refractarius, meaning “obstinate” or “stubborn,” derived from refringere (“to break up/back”), combining re- (“back”) and frangere (“to break”).

Containing the molten metal and making it into a form is the main concern, and it can be complex and expensive to attain.

In my studies in trying to develop a casting process for materials, barriers of entry have been fairly prominent, especially when going beyond casting lower temperature materials such as aluminum, brass, zinc, magnesium etc.

For example, the crucibles that are used for aluminum tend to degrade after a year of use. Studying what others have encountered I noticed also that the crucibles tend to go bad really fast when the temperatures get higher.

In fact, the crucibles that are sold are not intended for casting steel or cast iron, as they will crack or rapidly degrade. Deep discussions with furnace manufacturers and foundry supplies has been very insightful showing that the market is really tailored around low temperature alloys, not high temperature alloys such as iron and steel.

The type of furnace require to cost effectively melt steel and iron is an induction furnace. Barriers to entry are pretty obvious when it comes to purchasing that equipment. Even the old school method, say you were to use just basic coal and blowers, or even propane, the amount of time and energy required to get a simple crucible of material is immense.

The amount of time is about 2 hours and the amount of fuel is about 50 pounds of propane, and that is for one crucible of material, that is questionable in content at that!

I am the ultimate do-it-yourself-er, however as time gets more precious to me, some barriers to entry have a reason. There is a reason there was a Bronze age and an Iron age: the metallurgical leaps required to jump from simple bellows operated furnaces to large constructed (read investment) furnaces with high powered motors to keep the furnace fed with air is nothing to be scoffed at.

There are obviously other barriers to entry such as material content (different metallurgical formulations), heat shielding, proper safety equipment just to mention a simple few.

This is where finding a local iron foundry is key. Again the free market has your back.

Developing sand molds is the issue, if you have a mold, someone will cast it for you.

Developing The Sand Mold

- Design the Part

- Add machining allowances

- Add Shrink

- Add Runners

- Add Risers

- Package Assembly

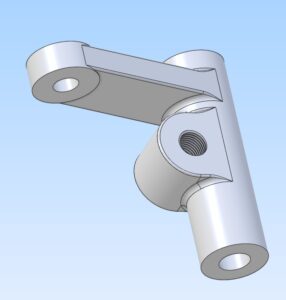

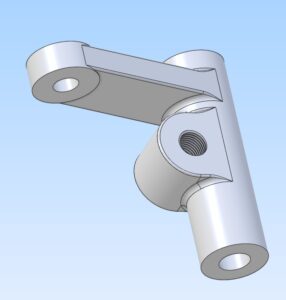

Design Part -Part Designed in Alibre.

Check part for fit

Validate part dimensions with SLA print. AnyCubic Printer

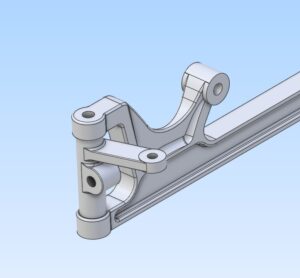

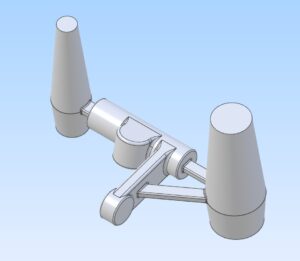

Design Casting features, add shrink, add runners and risers

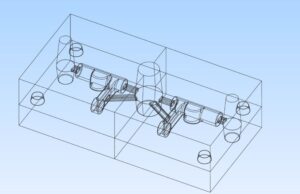

Assemble mold sections and verify functionality

Once the mold has been developed the next process is to make a form that the sand can be made around.

This is where 3D printing and simple CNC routing can minimize the costs.

In the case of the following cast iron part, the mold shapes were developed using basic CAD. From there a solid model was machined out of foam. The advantage of foam is that it is relatively cheap, is not hard to machine and errors can be fixed relatively easily by re-machining a new pattern shape.

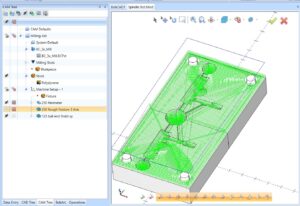

Generate tool paths. In this case using BobCad software. (Note: BobCad’s software is very intuitive and their support is phenomenal.)

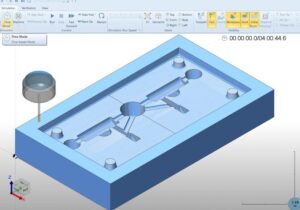

Full preview of tool paths completed, verify cutting expectations. What is shown is what you get.

Completed foam molds. Now getting ready for mold transfer. Details are excellent.

Typical CNC router set up, total time per mold set around 8 hours max.

The final sand mold form is then made by pouring silicone rubber over the foam shapes. Once the foam has been removed from the rubber, the sand mold shape is easily accomplished by packing resin sands into the molds and then wait until they cure. Extraction of the sand mold is then easily accomplished. Adding draft makes removal of the sand from the mold easier, but it is not necessary. Having minor undercuts can be achieved using the rubber mold method. The biggest advantage is having vertical or zero draft walls.

Example of a rubber mold making a sand mold

The rubber molds will shrink over time, however if serious need for minimal rubber shrinkage is a factor, then different rubber formulations can be used to attain the best dimensional results.

Breaking into small markets is easily attainable with this method, thus allowing complex parts with minimal up front tooling cost. These methods are very competitive and even can yeild better results compared to foreign manufacturers who rely mainly on old school pattern set ups.

High attention to detail can be attained with minimum cost.

You may be asking, why not just CNC machine the parts out of steel?

That actually is a fair question seeing all you have to do is place a chunk of material in the CNC machine and wallah, out comes a fantastic part….uh…no.

There are a couple of reasons why casting a part is better than CNCing out the part.

- Very often CNC machining requires two to three different set-ups to get the part in its final form.

- Machining time compared to casting is much different. A simple part may take 2 hours in machining time, compared to casting and secondary machining the same part, which may take a total of 1 hour.

- Machining takes time away from the CNC machine for more profitable parts.

- Replacement parts that were originally cast may have a cosmetic requirement that necessitates a cast finish. Very often restorers will require authentic parts for replacement.

- Small run casting can be accomplished, versus large orders for CNC’d parts to get the best price.

To recap, the purpose of this article is to show that developing sand molds (versus green sand patterns) is highly achievable with remarkable dimensional accuracy and surface finish. The highly achievable part is attained by using simple technologies that rival complex systems in the market place, for example 3d Sand Printing vs 3D routing rubber molds. The same complex mold in many instances can be achieved by extracting sand molds from the rubber mold in minutes versus 7 to 8 hours for one set of molds 3d Sand Printed.

First Castings of the front spindles. Came out excellent.

First castings of the front axle came out fairly decent accept for some minor shrinkage issues. These will be addressed by adding risers, which are simple inserts.

Shrinkage of boss section. Needs to be addressed or voids and porosity will weaken this section.

If you are interested in developing a new project but have been hesitant to do so, go to our contact page and leave a valid email and phone number and we will get back to you. Our many years of product development and unique approaches to market solutions is our expertise.